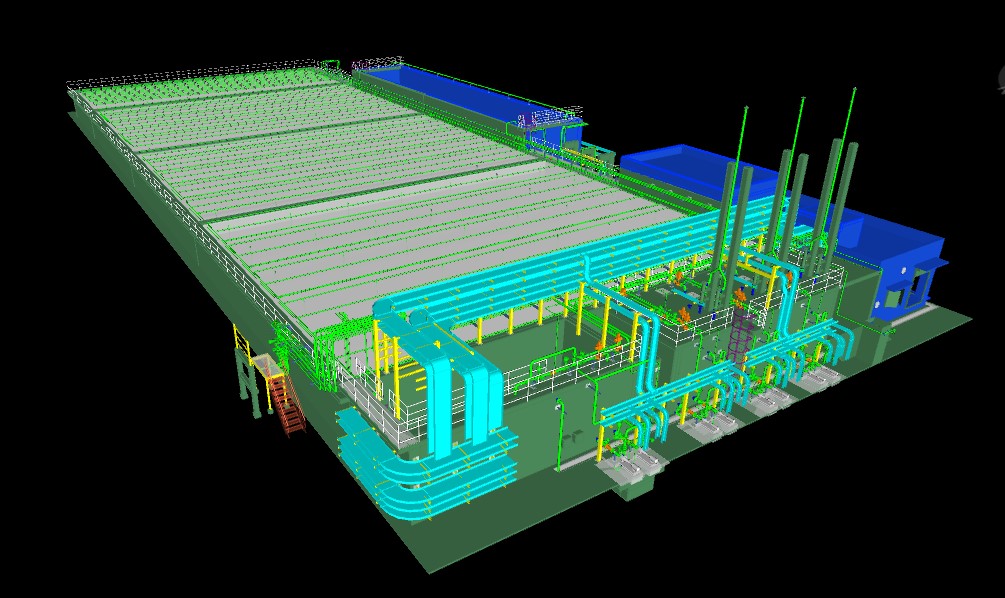

Effluent Treatment Plant

SBT system for Industrial Effluent Treatment Plant

Soil Biotechnology (SBT system) is an innovative approach for Industrial wastewater treatment. SBT is a cost effective technology that removes a wide range of contaminants from wastewater thereby transforming dirty, polluted and unhealthy water into clean, safe and pure water. The process is capable of treating all types of water – domestic, municipal and industrial including oxygen demanding wastewater generated by various industries.

It is most effective against wide range of recalcitrant molecules which are otherwise difficult to handle in conventional wastewater treatment process. This has made its application suitable for polishing of the existing ETPs, effluent with low BOD concentration and in particularly the treatment for MEE condensate effluent which otherwise is cumbersome task. Various other challenging applications are also explored with SBT system.

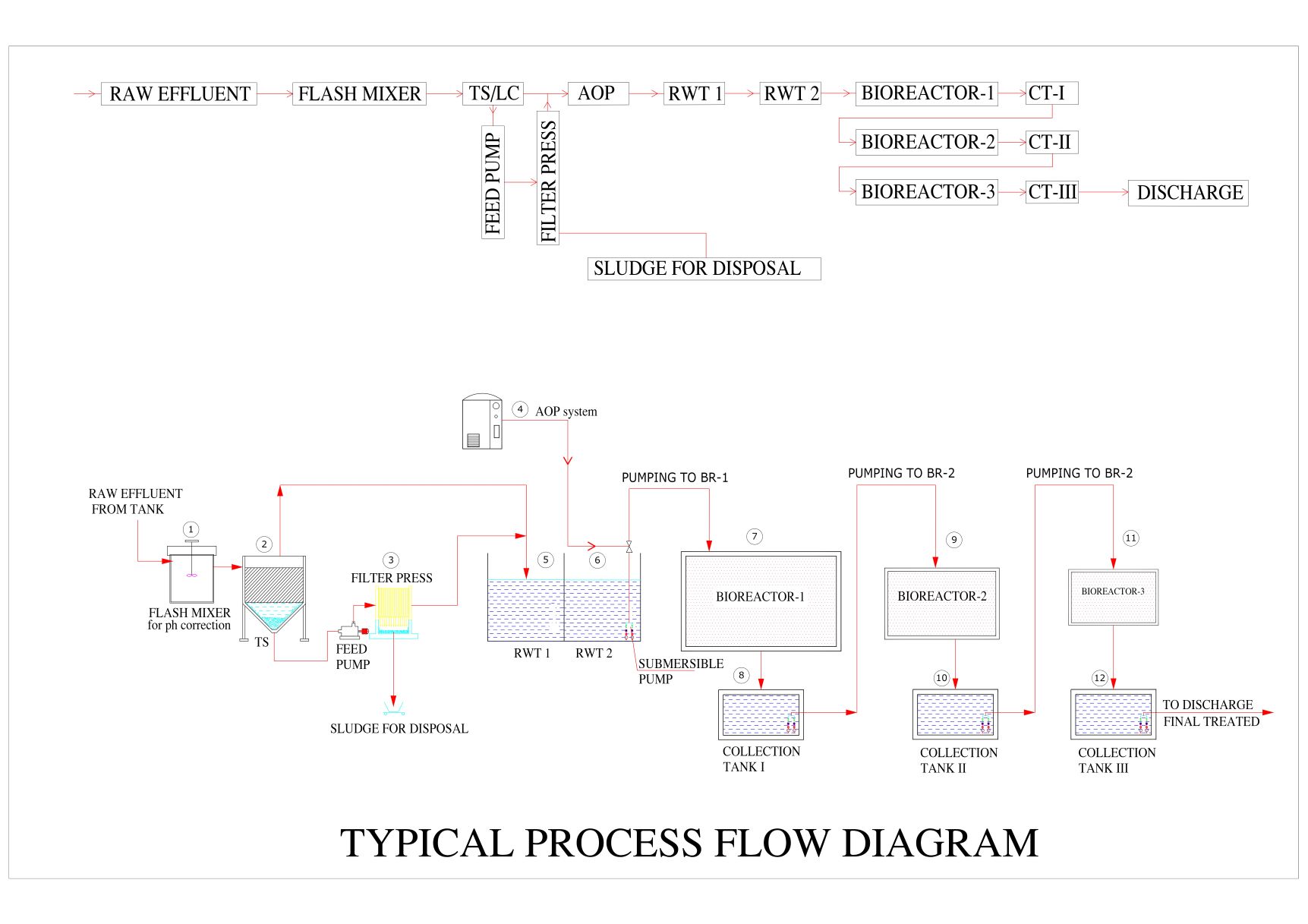

Process Description

Effluent free from Suspended solids shall only be subjected to Lifting Sump filling first

Step 1: Filling up of Lifting Sump tank with effluent

Considering the pH range given in the inlet parameters, if required pH adjustment shall be done in the SBT complex. SBT operating pH range is 5.5 to 9.5 and during which no pH adjustment is required.

Step 2: Filling up of Advance Oxidation System

Effluent from LS will be pumped to Advance Oxidation Systems. There will be online analyzer installed at common header of delivery line to check and confirm the inlet parameters (pH, BOD, Color, COD, Ammonia-N, cyanide, TSS and TDS). If the parameters are within range as defined in the inlet parameters then it shall be taken to Advance Oxidation system.

Step 3: Advance Oxidation Process as pre treatment

Combination of Advance Oxidation System shall be used as Pre treatment herein. The objective would be to enhance biodegradability of the effluent.

Step 4: Biofiltration

Pre treated effluent will then be Bio filtered in series. Following would be the permutation & combination available for Bio-filtration: Parallel mode/Standby mode/ Series mode.

Filtration through SBT system will be a batch processes in which wastewater is generally pumped and applied onto the top surface of the Bioreactor via submersible pumps and distributed or spread over the top surface of Bioreactor using uPVC distribution grid. Water first percolates through each bioreactor media in approx. 25-30 min which in houses cultured media and percolated effluent gets collected into the collection tank.

Step 5: Final discharge

Final effluent will be collected into CT3. There will be online analyzer (Analyzer No. 3) at discharge line within the boundary limit of SBT complex which shall be discharging effluent. Effluent complying to discharge norms as specified for - pH, BOD, Color, COD, Ammonia-N, cyanide, TSS and TDS will be allowed to be discharged.

In Industry, technology is being extended for zero liquid discharge for following applications namely:

- Pharma (API & Formulations)

- Petrochemicals

- Agrochemicals

- Specialty chemicals

- Chemical Research Organizations

- Biotech Industries

- Pesticides

- Textile

- Dyestuff & Dye Intermediates

- Wineries & Distilleries

- Paper & Pulp Mills

- Pigments & Dyes

- Food & Beverages

- Sugar